Training workforce in welding and painting is not easy. Traditional methods need a lot of raw materials, money, and time. On top of that, new trainees face risks like burns, fumes, and accidents.

This is why many companies are now choosing AR/VR training simulators. These simulators make training safe, repeatable, and cost-effective.

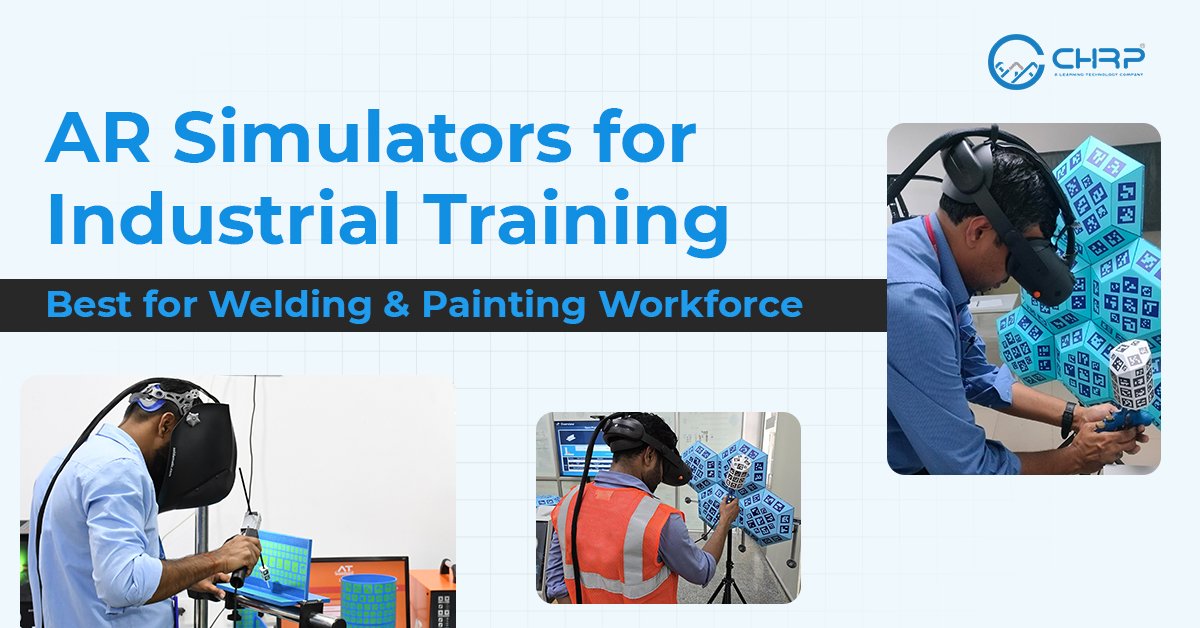

At CHRP-INDIA, we are the official partner for Seabery in Asia. It is a global leader in AR simulators for welding and painting. Our main products are:

Let’s explore how each of these simulators helps industries save money, improve safety, and build skilled professionals.

What is a Welding Simulator?

A welding simulator is a system that copies real welding with the help of Augmented Reality (AR).

Instead of using fire, gas, and metal, the trainee practices welding with virtual tools. The simulator shows realistic visuals, sounds, and feedback, so the experience feels close to real welding.

This means:

- Workers can practice without danger.

- Companies don’t waste rods, plates, or electricity.

- Trainers can check results instantly and guide students better.

Why Choose AR/VR Simulators for Training?

Using AR/VR simulators has big advantages:

- Safe learning: No exposure to heat, fumes, or sparks.

- Lower costs: No waste of materials during practice.

- Faster training: Employees get real-time feedback and improve quicker.

- Better retention: Trainees remember skills longer when they practice in an immersive environment.

- Eco-friendly: Less material waste and pollution.

AR Simulators – Three Powerful Simulators

1. Soldamatic – The Global Welding Training Leader

Soldamatic is the most widely used AR welding simulator in the world.

Highlights:

- Patented Hyperreal SIM technology makes practice feel like real welding.

- Supports multiple welding types: MIG, TIG, Stick, and Flux-Cored.

- Gives instant feedback on mistakes like torch angle, speed, or distance.

- Saves huge costs by reducing material use.

2. AT Weldsim – Blended Learning for Welders

AT Weldsim is designed for a complete learning process.

How it works:

- First, the trainee learns the theory of welding.

- Then, they practice safely in AR with a simulator.

- Finally, they move on to live welding with real equipment.

Benefits:

- Trainees build confidence step by step.

- Trainers get clear data on performance.

- Training time is reduced, while results improve.

AT Weldsim is perfect for training centers, technical institutes, and companies that want structured skill development.

3. Paintomatic – Smart Spray Painting Training

Painting is a skill where mistakes are costly. Paintomatic gives a virtual environment for spray painting.

Why it’s effective:

- Simulates real spray guns for practice.

- Shows feedback on distance, angle, and paint thickness.

- Cuts paint waste and reduces harmful emissions.

- Builds professional painting skills at a lower cost.

Paintomatic is widely used in automotive, construction, and manufacturing industries.

Benefits Across All Simulators

Whether it is Soldamatic, AT Weldsim, or Paintomatic, the benefits are the same:

- Faster onboarding → train new workers quickly.

- Cost savings → reduce raw material waste.

- Workplace safety → no risks during early practice.

- Eco-friendly → less pollution and waste.

- Better results → workers remember and apply skills better.

Conclusion

Training workers doesn’t have to be slow, risky, or expensive. With Seabery’s Soldamatic, AT Weldsim, and Paintomatic, companies can:

- Save money,

- Improve worker safety, and

- Build skilled professionals faster.

At CHRP-INDIA, we bring Seabery’s world-class simulators to organizations across Asia.

Ready to experience the future of training?

Visit & book a demo today.