AR simulators use real-life tools but with virtual environments; this means that learners go through the process of welding or painting just like they would in an actual workshop, without the associated risks or costs.

Here’s how they make the difference:

1. Immersive and Realistic Training

These AR simulators introduce the trainee to a realistic 3D environment in which real torches, spray guns, or welding masks fitted with sensors are used. They show real-time virtual weld pools, flame behaviors, or paint spray patterns. This simulation reacts dynamically to hand movement, angle, speed, and distance-just like real industrial scenarios.

2. Instant Feedback and Assessment

First among the advantages is the data-driven performance tracking by simulators such as Soldamatic and ATweldSim. Each exercise is recorded and analyzed, measuring parameters of travel speed, arc length, and angle in relation to heat input. Immediate feedback is thus provided, enabling the trainees to rectify mistakes at a very early stage and improve faster. Instructors can generate detailed performance reports to ensure standardized, objective assessment across batches.

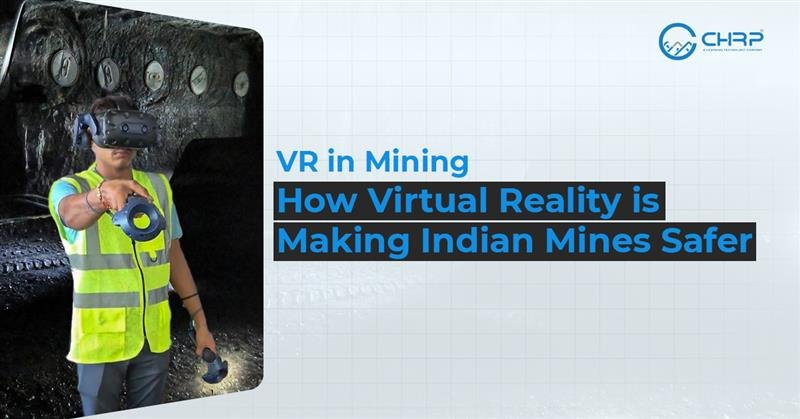

3. Safety Without Compromise

Safety is the main concern that is integrally linked with welding and painting. AR simulators exclude exposure to heat, sparks, gases, or toxic fumes by letting starters learn in safety with no danger to themselves or others. A safer learning environment gives an instructor opportunities to build confidence in learners before going into real-world tasks.

4. Cost and Resource Efficiency

These AR simulators drastically reduce consumables in training; hence, no actual electrodes, metal plates, paint, or gas are used. These save a great amount on materials, maintenance, and energy for institutions while providing high-quality and repeatable training sessions.

5. Sustainability and Environmental Benefits

As a result, waste and emission reduction has become a priority in most industries around the world. Virtual training does not emit hazardous by-products including fumes, dust, and leftover materials. It therefore supports green, sustainable training methods that are in compliance with global environmental standards.

Top AR Simulators Reshaping Industrial Training

1. Soldamatic: Most Advanced Welding Simulator in the World

SoldaMatic by Seabery is the first AR welding simulator in the world, offering unparalleled realism and precision in training. It allows the learner to practice different kinds of welding processes: MMA, MIG/MAG, TIG with real torches, and augmented reality welding helmets.

Key Features:

True-to-life welding simulation, including physics-based visual effects.

- Real-time performance analysis and instructor dashboard.

- LMS Integration: Learning management systems that can track activity.

Multilingual, modular training content according to international norms and standards: AWS, ISO, EN

Benefits:

The institutes and industries working with Soldamatic have reported a reduction in training time as much as 68% and a material cost decrease of up to 84%, hence making Soldamatic one of the best training tools today.

2. ATweldSim: Immersive AR Welding Training

Another powerful solution for practical skill development in welding is ATweldSim. It targets vocational training centers and industrial training institutions to let students realistically simulate various types of welding techniques, offering flexibility in portability for training.

Key Features:

- 1:1 replica of real welding tools with integrated motion sensors.

- Realistic simulation of the weld pool, torch behaviour, and arc sound.

- Difficulty levels adjustable from beginner to expert levels.

In-depth error tracking and scoring system for continuous improvement.

Benefits:

ATweldSim fills the gap that exists between classroom theory and field practice by enabling trainees to develop muscle memory, precision, and safety awareness-all this without ever having to enter an actual workshop.

3. Paintomatic: AR-Based Spray Painting Simulator

While simple in nature, industrial spray painting is a job of precision and consistency, besides concern for environmental safety. With the ability to replicate realistic spray patterns, gun handling, and surface coverage in a highly controlled digital environment, AR at Paintomatic introduces new dimensions in paint training.

Key Features:

- High-fidelity AR interface to simulate the flow, distance, and coverage of paint.

- Real-time feedback on gun angle, overlap, and paint thickness.

- Deep analytics on skill assessment and progress tracking.

- Application-specific modules for automotive, marine, and industrial coatings.

Benefits:

Paintomatic prevents any waste of paint and avoids toxic exposure for safe, eco-friendly, cost-effective training for both beginners and professionals.

The Measurable Impact of AR-Based Training

Organizations that include augmented reality simulators within their training programs register the following key and tangible benefits:

- Faster Mastery of Skills: It takes less than half the time to reach proficiency levels compared to conventional methods.

- Lower Training Costs: Consumables, workshop maintenance, and instructor time are greatly reduced.

- Higher Training Capacity: Several trainees can practice all at once using shared systems.

- Knowledge Retention improves due to the interaction in learning that enhances memory and understanding.

- Improved Safety Indicators: Reducing workshop accidents, fewer near-miss incidents during training.

Building the Future Workforce with AR Training

Given the focus of India on skill development and industry-readiness, technologies such as AR simulators will form the backbone for molding the employees of the future.

CHRP-INDIA takes pride in presenting world-class simulation technologies such as Soldamatic, ATweldSim, and Paintomatic to institutions and industries throughout the country. These tools increase efficiency in the training of an organization and are further aligned with the objectives of Industry 4.0 and Skill India toward innovation and sustainable learning.

Be it an Industrial Training Institute, corporate training facility, or even government-led skilling programs, AR simulation offers a scalable, safe, and measurable route toward building skilled professionals who are ready for real-life applications.

Conclusion

While AR simulators represent further evolution in the way vocational training is imparted, it combines technology with safety and sustainability in order to build highly skilled, job-ready professionals. Such high-risk trades as welding and painting have stepped into a new era of innovation and precision through immersive, data-driven learning.

Get Started with AR Simulation Today

Introduce the future of technical training at your institution with CHRP-INDIA advanced AR simulation solutions. Learn from Soldamatic, ATweldSim, and Paintomatic about how they are saving costs and improving safety while creating measurable impacts on learning outcomes. Want to see a live demo or explore partnership opportunities? Contact CHRP-INDIA today.